Local Pickup FAQ's

Hover to zoom

1 Of 5

+

Share This Product

Recommended Accessories

Expert Recommended Accessories

Selected by Jim, our Expert

Required Accessories

9

These accessories are required to properly setup/install this product.

Optional Accessories

10

Features

Style

Primary

GPH

2680 Gallons

Switch Type

None

Product Video Disclaimer: "PED is not responsible for any variances from the product in this video and the item you purchase. Please review all product specs prior to purchase."

- ***NON-AUTOMATIC - Requires Float Switch***

- Submersible Cast Iron Sump Pump

- Offers years of reliable, trouble-free operation

- No Sheet Metal Parts To Rust Or Corrode

- Stainless steel screws, guard, handle, arm and seal assembly

- Thermally Protected, Permanent Split Capacitor Motor

- Oil-filled and hermetically sealed to prevent overheating

- Carbon & Ceramic Shaft Seal

- Assures maximum protection for extended pump life

- Powder Coated Epoxy Finish

- Provides a corrosion resistant exterior

- Clog-Resistant Design

- No screen to interfere with flowing debris

- Capable of passing 1/2" diameter solids

- Industry Leading Quality Control

- Entire unit is pressure tested after assembly

California residents see

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov.

For more information go to: www.p65Warnings.ca.gov

Specifications

53-0002

General Information

Product Category

Sump Pump

Base

Base Material

Thermoplastic

Min Sump Basin Size

18 Inch

Motor

Voltage

120 Volt

Running Amps

9.6

Thermal Protection

Yes

Power Cord Length

15 Feet

Oil Free Motor

No

Starting Amps

25.9

Pump

Housing Material

Cast Iron

Impeller Material

Plastic

Solids Handling Size

.5 inch

Handles Solids

Yes

Float Type

No Switch

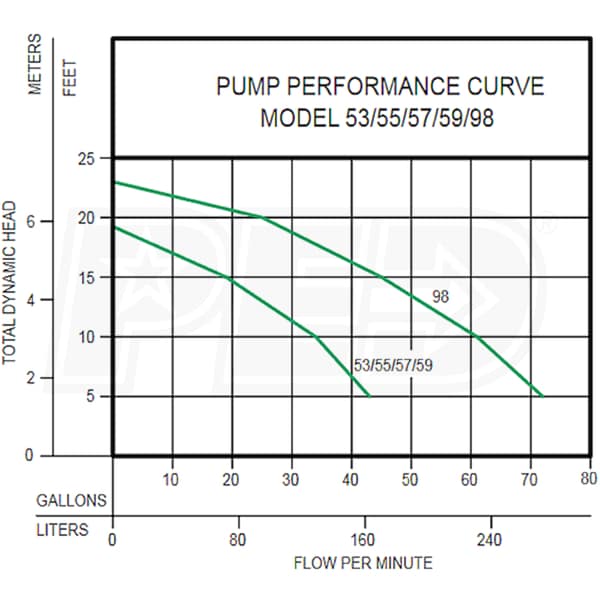

GPH @ 0 feet

2680

GPH @ 5 feet

2680

GPH @ 10 feet

2040

GPH @ 15 feet

1140

Discharge Port Size

1-1/2 Inch

Check Valve Included

No

Manual Override

Yes

Max Head

19.25 Feet

Submersible

Yes

Engine

Horsepower

.33 HP

Overview

Product Category

Sump Pump

Weight

20 Pounds

Consumer Warranty

3 Years

Product Length

10.2 Inches

Product Width

7.5 Inches

Product Height

10.2 Inches

UPC

053514023614

Additional Model Numbers

N53, 53-0002

Reviews

(101)

Zoeller 53-0002 Reviews & Ratings

Product Q&A

(6)

Product Questions

Answered by Jim, the Sump Pump Expert

Why does my Zoeller 53 pump make noise but not pump water out?

William

from Connecticut

March 15, 2017

I just replaced my float for a Zoeller BN53-C...I noticed the wire on the float and the pump is brittle and deteriorating even when I strip the wire back 12 or more inches, is this common problem?. Can pump be rewired, and is there a rewire kit or do I need to buy a new pump? I want the same Zoeller pump but I do not need a new float as I just replaced the old float switch. Also, the new float is not kicking on, and my alarm is going off for high water. I followed the directions. Should I shorten its tether length? Currently it is at 4.5 inches from stack to float. I have a few more technical questions too can you contact me? Hope to hear from you TUESDAY 7/5. Phone:440-214-2047

Paul Mihacevich

from Ohio

July 04, 2016

My Zoller pump has a threaded female connector on the body. What am I expected to put between the pump body and the bottom clamp of this check valve?

BN

from California

September 17, 2014

I have a small catch basin aside my house with underground drain line that runs to the street. Drain line collapsed under sidewalk and with heave rain, catch basin backs up, overflows and I get water in my house. Thinking of putting this pump in the catch basin with a line out to pitched front lawn so when water reaches a certain level in backed up basin it will turn on and pump water out. Does that sound like a fit for this pump?

Gary B

from New York

June 06, 2013

Is any maintenance required on the M53 pump? I see there are two white plugs on the pump and I'm wondering if oil needs to checked or added periodically or any other type of maintenance is needed.

Jim M

from Nebraska

December 22, 2012

I am torn between which Zoeller pump would be best for my application. My basement is 104' and currently takes in approximately 3" of water when there is a hard rain. The water is only on one side of the basement and never comes up on the other. Would you recommend a 1/3 hp or 1/2?

Joe

from New Jersey

January 15, 2012

How-To Articles

How To Pick The Perfect Pedestal Sump Pump

Pedestal sump pumps sit on a pedestal that keeps them out of the water. Unlike ...

Introducing Goulds Pumps

Born, raised, and built in the U.S.A., Goulds Water Technology is an American m...

How To Pick The Perfect Submersible Sump Pump

Submersible sump pumps are the preferred choice for most residential applicatio...

Manuals

Ask A Question!

*Required Fields

+

Thank You For Submitting Your Question

Your submission has been sent successfully. Please give our experts up to two business days to respond.

Thank You For Submitting Your Question

Your submission has been sent successfully. Please give our experts up to two business days to respond.

Media Gallery

Zoeller N53 - 1/3 HP Cast Iron Submersible Sump Pump (Non-Automatic)

Customer Review Images