Local Pickup FAQ's

Hover to zoom

1 Of 5

Zoeller ProPack98 Spin - 1/2 HP Combination Primary & Backup Sump Pump System

Model:

508-0007

+

Share This Product

Recommended Accessories

Expert Recommended Accessories

Selected by Jim, our Expert

Required Accessories

9

These accessories are required to properly setup/install this product.

Optional Accessories

10

Features

Style

Combo

GPH

4320 Gallons

Switch Type

Vertical

Product Video Disclaimer: "PED is not responsible for any variances from the product in this video and the item you purchase. Please review all product specs prior to purchase."

- Zoeller Pro Pak 98 - Primary & Backup Sump Pump System

- Simply attach inlcluded discharge pipe & you're ready to install

- 1/2 HP Cast Iron Primary Pump w/ Vertical Float Switch

- Engineered thermoplastic base for extended pump life

- Oil-filled and hermetically sealed to prevent overheating

- 12-Volt, Highly Efficient Backup Sump Pump (6' Leads)

- Non-corrosive design w/ Integrated Check Valve & Pump Legs

- Pumps 2340 gallons-per-hour @ 5' lift (or 1800 GPH @ 10')

- Built-In Alarms

- High Water, Low Battery & Reverse Polarity

- 10-Amp Battery Charger & Control Box

- Self-contained design w/ Battery burnout & overcharge protection

- Displays battery voltage & important system information

- LED Light Indicators & Buttons

- For system status; AC Power, Charged, Charging & Low Battery

- Plus High Water, Alarm Off button & Scroll display button

- Compact, low-voltage Vertical Float Switch For Backup Pump

- Corrosion-Resistant Box Fits Group 27, 29 or 31 Batteries

- Furnished With All Required Fittings - BATTERY SOLD SEPARATELY

- 3-Year Warranty

- For Indoor Use Only

California residents see

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov.

For more information go to: www.p65Warnings.ca.gov

Specifications

508-0007

General Information

Product Category

Sump Pump

Base

Base Material

Thermoplastic

Min Sump Basin Size

18 Inch

Motor

Voltage

12 Volt DC/120 Volt AC

Battery Included

No

Thermal Protection

Yes

Power Cord Length

9 Feet

Oil Free Motor

No

Pump

Housing Material

Cast Iron

Solids Handling Size

.5 inch

Float Type

Vertical Float

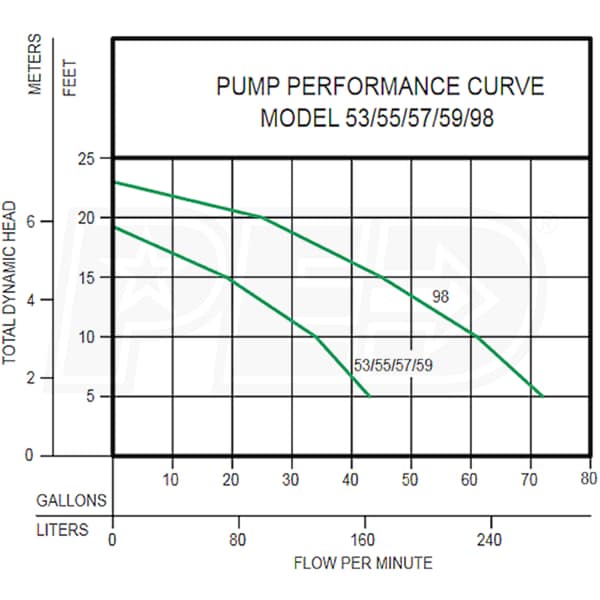

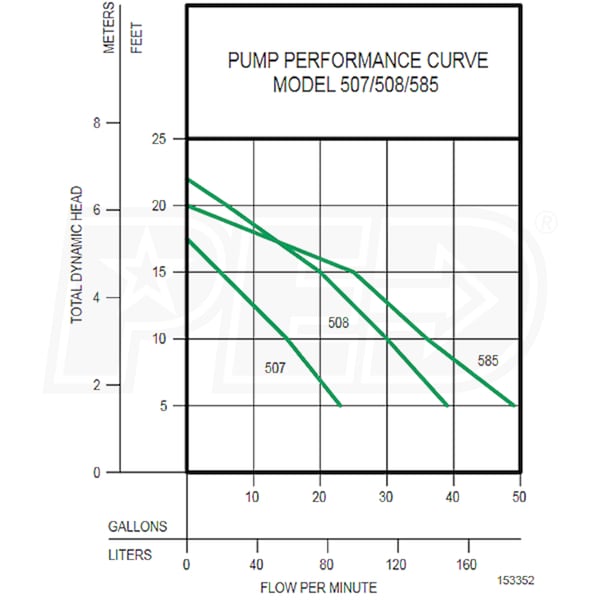

GPH @ 0 feet

4320

GPH @ 5 feet

4320

GPH @ 10 feet

3660

GPH @ 15 feet

2700

GPH @ 20 feet

1500

Backup GPH @ 0 feet

2340

Discharge Port Size

1-1/2 Inch

Check Valve Included

Yes

Float On

9.5 Inches

Float Off

3 Inches

Manual Override

No

Backup GPH @ 5 feet

2340

Backup GPH @ 10 feet

1800

Backup GPH @ 15 feet

1200

Backup GPH @ 20 feet

360

Engine

Horsepower

.5 HP

Overview

Product Category

Sump Pump

Assembly Required

Yes

Weight

43 Pounds

Consumer Warranty

3 Years

UPC

053514348762

Reviews

(71)

Zoeller 508-0007 Reviews & Ratings

Product Q&A

(3)

Product Questions

Answered by Jim, the Sump Pump Expert

The description says that it requires an 18-inch sump basin. Our basin is 18 inches in diameter at the top but slopes down to 16 inches at the bottom. Will this model fit?

Mason M.

from Ohio

August 30, 2018

Do I need this check valve with the 508-0007 pump system or will the check valves built into it do the same thing? My current sump pump installation has a check valve above the pump just above the pit level. There is also a small hole drilled into the pipe between the sump pump and the current check valve. Will the 508 system need this hole also? I'm not sure what the hole is for, it just sprays a bit while the pump is running and then lets this section of pipe drain. The instructions included with the 508 don't mention either of these features, I just wanted to double check with you before I eliminate them.

Brad T.

from Utah

February 07, 2017

I have no experience with battery back-up systems but I'm considering this system for purchase. It does not include a battery. What type and size battery is optimally recommended for this system?

Kevin

from New York

April 08, 2015

How-To Articles

How to Pick the Perfect Combination Sump Pump

The Rolling Stones once famously sang, "You can't always get what you want." Of...

How to Keep Your Basement From Flooding

The last thing you need is a tidal pool of sewage infiltrating your basement. ...

How To Pick The Perfect Submersible Sump Pump

Submersible sump pumps are the preferred choice for most residential applicatio...

Manuals

Ask A Question!

*Required Fields

+

Thank You For Submitting Your Question

Your submission has been sent successfully. Please give our experts up to two business days to respond.

Thank You For Submitting Your Question

Your submission has been sent successfully. Please give our experts up to two business days to respond.

Media Gallery

Zoeller ProPack98 Spin - 1/2 HP Combination Primary & Backup Sump Pump System

Customer Review Images